Description

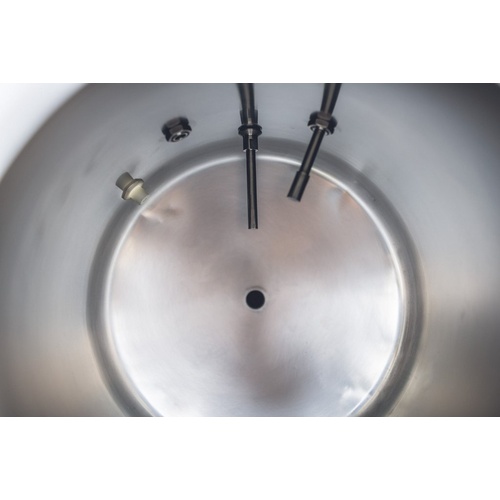

Continuing its dream of homebrew brite tanks, Ss Brewtech is releasing a 1 BBL brite tank. Brite tanks provide one vessel that can age and store your beer instead of splitting it up into kegs or bottles. The Brewery style dished bottom and drain gives the yeast a larger surface to settle and prevents yeast from getting drawn into the serving line. The provided sight gauge and digital thermometer allow you to monitor your beer while keeping it sealed from the environment. It also has a 15 psi operating pressure which allows you to use the built in carbonation stone and pressure gauge to carbonate your beer.

Specifications:

1.5 mm thickness 304 Stainless Steel

37.5 gallon capacity

24” Diameter

32” Height

27” Depth (with valve)

We design all of our products with safety as an overarching concern, which is one reason why these vessels are vigorously tested at 4x their recommended operating pressure. Once the fabrication of the first production golden sample is complete, the unit is sent to a lab, where it undergoes a series of tests to insure that the vessel conforms to our strict standards. These tests are performed in a lab environment by SGS, a global leader in inspection, verification, and testing certifications.

A Brite Tanks Functionality:

1. Cuts carbonation time down significantly with a carb stone, so users can fully carb in under 24 hours. In comparison, the “low and slow” method might take a Home Brewer 5-7 days to fully carbonate in a corny keg. Plus the brewers that try to burst carb at much higher pressures risk carb bite, or a carbonic acid flavor, which is simply over carbonated beer.

2. Allows for proper burst carbing and head pressure monitoring. Commercial breweries do the same thing, they may set input pressure to their carb stones at 30 PSI, then monitor the head pressure until the desired carb limit is reached, typically 12-13 PSI. Then turn down the CO2 to a reasonable serve pressures.

3. Allows for bulk conditioning/aging. This is seriously underrated, if a 10 gallon home brewer can store and serve their beer all in one vessel, it will age differently, plus you only have one vessel to clean and turn when it’s time to refill.

4. Has a larger center drain instead of a dip tube, so yeast is not drawn into the serving line. Just like a commercial brite tank, the large center drain allows for low-velocity pickup, as opposed to a small dip tube in a corny keg, which is a high-velocity pickup. The high velocity of the corny dip tube results in more yeast and sentiment drawn into the draught line.

5. Has a larger bottom surface area for yeast to settle onto. For the volume of beer, corny kegs have a relatively small bottom surface area compared to the Brite Tank. This allows yeast to settle and gather throughout the lower surface area.

6. Can be used as a Firkin/cask ale device. Most home brewers go to a lot of expense for cask ales and firkin kegs, our Brite Tank allows a home brewer to hook up a beer engine, disassemble the PRV seal and use the small opening as the spile.

7. Integrated LCD/Thermowell. For the homebrewer that closely wants to monitor both serve or lager temp, alongside calculating exactly how many volumes of CO2 is going into their beer, a thermowell and thermometer are key. Kegs don’t have this functionality.

8. Easier to clean/CIP. CIP has proven to one of the more popular features and purchase decision drivers for our BME Chronical line. We will be introducing a reducer so the end user can utilize their existing equipment investments in CIP on multiple vessels. Plus, cleaning kegs is awful, it’s much easier to throw in some caustic or sanitizers and let the pump and spray ball work their magic.

9. Integrated legs with option for casters. We have come across many homebrewers that are not as young as they used to be and kegs may occasionally need to be lifted. By enabling the use of casters, it makes material handling throughout a home brewery that much easier, just roll it around.

10. Ability to serve and function externally with the use of glycol chiller. Kegs can’t function outside of a kegerator or some other sort of refrigeration device. Equip our optional BME coil and jacket upgrade and the brite tank can be rolled outside and served directly out of without the need for a refrigerator.

11. Ability to transfer beer from your fermenter from the bottom up. Many home brewers are obsessive about oxidation, as well they should be! With kegs, you either have to fill from the dip tube, which is a painfully long process and fraught with other issues, or you risk oxidation. With a Brite Tank, all you need to do is purge the vessel, then fill from the bottom with 1/2″ tubing. Transfers take just a few minutes.

Stainless Steel Prep

Pre-Clean: Prior to first time use, thoroughly wash all surfaces of the Brite Tank, including all valves and fittings, with Tri-Sodium Phosphate (TSP) in hot water, mixed to the manufacturer’s recommendations. Scrub with a soft terry cloth, and after the initial TSP wash, rinse thoroughly and dry all surfaces.

Passivation: It’s good practice to periodically passivate all stainless steel equipment with an acid based solution to establish a uniform passive oxide layer that will maximize corrosion resistance. Following the pre-clean step, fill the Brite Tank with Star-San at a concentration of 1 ounce per gallon at 70-80°F for 30 minutes. Retain Star San

solution for leak testing, see Pressure Testing section. Moving forward, for best stainless performance, passivation should be performed at least once a year or anytime you believe you may have inadvertently scratched the surface.

Cleaning and Sanitizing: As part of a regular cleaning regimen both pre and post-use, wash the interior surfaces of your Brite Tank with an alkali cleaner such as PBW at a ratio of 0.75 ounce per gallon. Then sanitize with Star San or another acid based sanitizer per the manufacturer’s recommendations. When not in use, store the carb stone in a strong Star San solution, or vodka, to avoid the pores from becoming clogged.

What’s in the Box

- Brite Tank

- 6” TC Cap

- 6” TC Clamp

- 6” TC Gasket

- Pressure Release Valve

- Pressure Gauge 90° Fitting

- Pressure Gauge

- (2) Sight Glass 90° Barbs

- Sight Glass Vinyl Tubing

- Hose Clamps

- Butterfly Valve

- Sampling Valve

- Carb Stone Valve

- 1.5” TC Clamp

- 1.5” TC Gasket

- 3/8” Threaded Stem Feet

- Thermowell Assembly

- LCD Thermometer

Reviews

There are no reviews yet.